Dashi Shuibiao Industrial Zone, Lihe Rd, Lishui Town, Nanhai Dist, Foshan, Guangdong, China

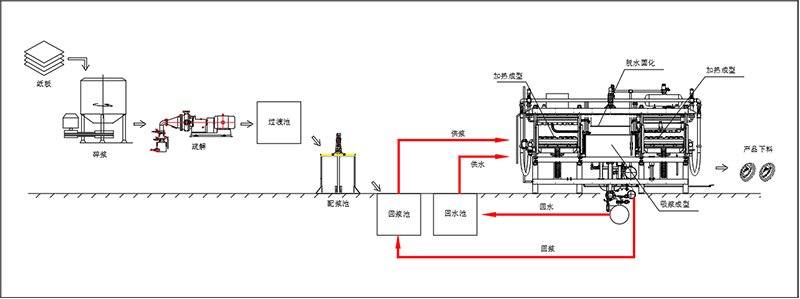

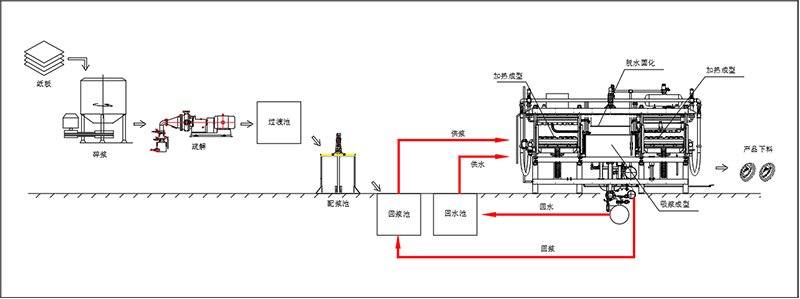

The main machine of pulp molding is the core molding equipment of the product. It is used in conjunction with the pulping system, vacuum system, high-pressure water system and air pressure system for the production and molding of disposable pulp molded products (such as cup lids, boutique work bags, etc.).

The equipment is for preparing a certain concentration of pulp by sugarcane pulp, bamboo pulp, wood pulp, reed pulp, straw pulp and other pulp boards ; then through the host wet green molding, drying and hot pressing processes to produce disposable pulp molded products, and finally pass the manipulator automatically fetches and send out with stacks automaticlly. The host system (such as 90 cup lids) has an average production capacity of 180,000 pieces per day. Professional customized solutions can be made according to the actual situation of customers.

YK-D1111

YIKAI

| Availability: | |

|---|---|

Main feature |

| 1) High precision, high stability, high productivity; |

2) Forming and shaping integrated automatic design; |

| 3) Offline automatic trimming design; |

4) Can produce all kinds of exquisite pulp molded products; |

| 5) The position, pressure and temperature can be precisely adjusted. |

| Equipment | |

| Forming station | 1 |

| Cold extrusion station | 1 |

| Hot pressing station | 2 |

| Internal transfer mechanism | 1 |

| Control system | 1 |

| Main data | |

| Template size | 1100x1100mm |

| Single machine capacity | 180,000 pieces/day (according to 90 cup lids) |

| Forming method | Single-sided slurry suction forming |

| heating method | Electric heating |

| Max.pressure (servo hydraulic) | 40T |

| Max. mold height | 450mm |

| Transfer method | Internal transfer |

| Blanking method (optional) | 6-axis industrial manipulator |

Main feature |

| 1) High precision, high stability, high productivity; |

2) Forming and shaping integrated automatic design; |

| 3) Offline automatic trimming design; |

4) Can produce all kinds of exquisite pulp molded products; |

| 5) The position, pressure and temperature can be precisely adjusted. |

| Equipment | |

| Forming station | 1 |

| Cold extrusion station | 1 |

| Hot pressing station | 2 |

| Internal transfer mechanism | 1 |

| Control system | 1 |

| Main data | |

| Template size | 1100x1100mm |

| Single machine capacity | 180,000 pieces/day (according to 90 cup lids) |

| Forming method | Single-sided slurry suction forming |

| heating method | Electric heating |

| Max.pressure (servo hydraulic) | 40T |

| Max. mold height | 450mm |

| Transfer method | Internal transfer |

| Blanking method (optional) | 6-axis industrial manipulator |